The Catalyst for Sustainable Chemicals

Despite the sometimes negative connotations, chemicals are a vital part of our lives, acting as the building blocks for everything from medicine to fuel to a vast array of consumer goods.

However, manufacturing these substances comes at a cost: Traditional methods often involve triggering reactions using difficult-to-mine precious metals at extremely high temperatures, pumping carbon into the atmosphere and exacerbating climate change.

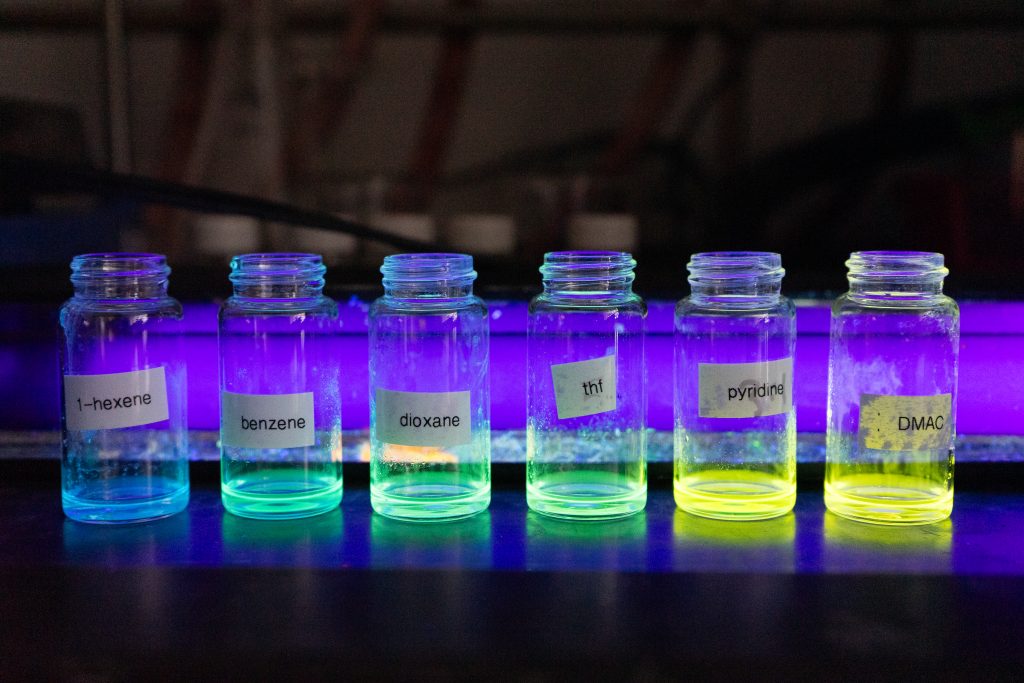

That’s why Colorado State University researchers are pioneering another solution through a process known as photoredox catalysis — inspired by the natural chemical reactions that happen in plants.

“Light is energy, you can feel it when you go outside, warming you up,” said Garret Miyake, a professor in the CSU Department of Chemistry. “What we’re doing is figuring out how to use light energy – which is milder and more sustainable than traditional methods – with catalysts to drive chemical reactions.”

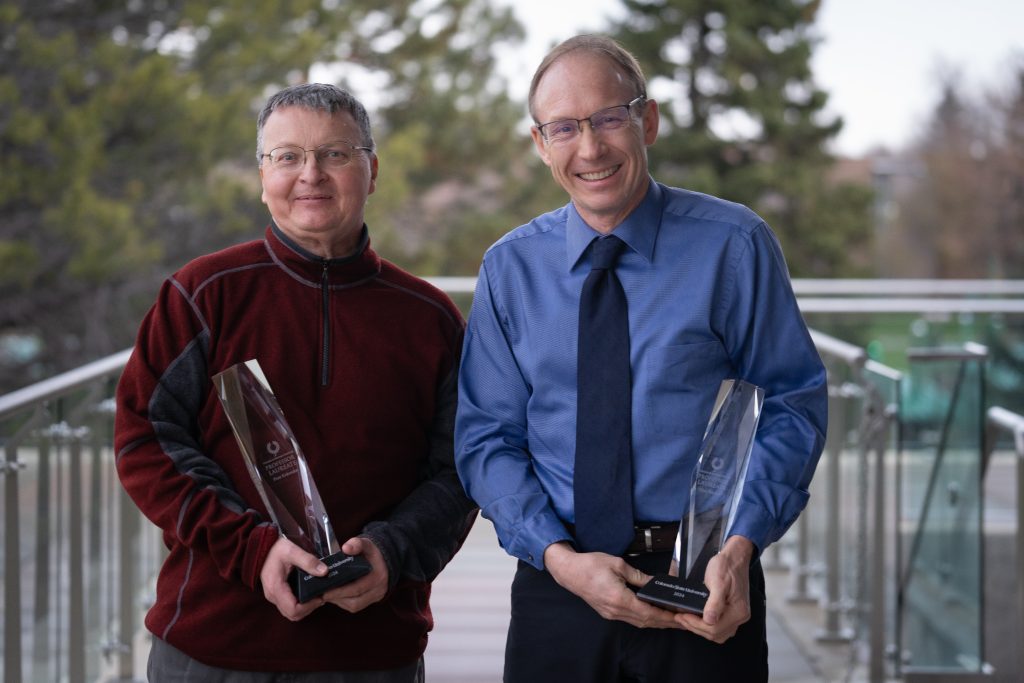

The National Science Foundation has awarded Miyake a three-year, $1.8 million grant to launch the Center for Sustainable Photoredox Catalysis, or SuPRCaT, which will design chemical manufacturing processes harnessing light energy and utilizing readily-available materials as catalysts.

Miyake will serve as the director and lead a multidisciplinary team of 12 other researchers from CSU, the University of Colorado Boulder, University of Wisconsin, University of Northern Colorado, Northeastern University, Metropolitan State University Denver and a startup called New Iridium.

This team was one of three selected to receive funding from the NSF Centers for Chemical Innovation. One will later be selected for a five-year, $20 million grant to further their research.

“We’ve established what I consider to be an all-star team so far of computational, spectroscopic and synthetic chemists to understand this process holistically,” Miyake said.

The center will be based at CSU, and part of its efforts will include designing a machine learning platform that allows researchers to identify new potential materials that could be used as catalysts as well as to optimize the performance of existing options.

Researchers will experiment with chemical reactions aided by LED lights in room temperature labs – a departure from more traditional chemical manufacturing facilities that sometimes rely on heating materials up to thousands of degrees.

“For our world to continue to thrive, we need to find better and more efficient ways to make chemicals,” Miyake said.